The industrial transport landscape is shifting—fast. For fleets operating on mining and resource-sites, considerations once centred exclusively on ruggedness, compliance and cost are now joined by sustainability, emissions, and future-proofing. Enter the concept of mine spec electric vehicles: purpose-built, site-ready EV or hybrid vehicles engineered (or up-fitted) to meet the rigorous demands of mining operations.

In this article we’ll explore:

- What “mine spec electric vehicles” really means in a mining context

- The major advantages (and real-world benefits)

- The key disadvantages and barriers

- Compliance and regulatory landscape in Australia

- Practical considerations for fleet managers assessing transition

- How hire-/rental-providers (such as Trend Rentals) fit into the picture

- Final thoughts and roadmap for implementation

What Are “Mine Spec Electric Vehicles”?

The term “mine spec” typically refers to vehicles modified or manufactured for use on mining-sites, with fit-outs such as rollover protection (ROPS), falling object protection (FOPS), fire-suppression systems, battery isolation switches, heavy-duty tyres, UHF radios, high-visibility markings and more.

When you combine that with electric (battery-electric) or hybrid drivetrains, you get what we’ll call mine spec electric vehicles—vehicles that:

- Are suited for the mining site environment (rough terrain, remote location, high durability)

- Have EV or hybrid propulsion (zero or reduced tail-pipe emissions)

- Meet mine-site vehicle compliance requirements (safety structures, fit-out, certifications)

For example, electric 4×4 platforms such as those from Rivian or MEVCO are explicitly marketed in Australia for “mine-spec EVs”. This signals that the shift is not just conceptual — the tech is in motion.

For fleets and hirers like Trend Rentals, who already supply site-spec and mine-spec hire vehicles, the logic is increasingly clear: aligning EV/hybrid options with mine-spec fit-out and operational readiness is the next frontier. (See their article on the future of mine-spec vehicles with EVs and autonomous systems.)

The Advantages of Mine Spec Electric Vehicles

1. Lower Emissions & Sustainability Credentials

Switching to electric (or hybrid) drives reduces tail-pipe emissions. This supports environmental goals, ESG reporting and helps mining companies meet decarbonisation targets. Australia’s regulatory push on emissions and fleet efficiency is growing.

2. Reduced Fuel & Operating Costs

Electric vehicles typically have fewer moving parts, deliver better site-efficiency (especially if used in stop-start or idle-heavy conditions), and can reduce maintenance costs (e.g., no diesel particulate filters, fewer fluid changes). Over a tough mining life-cycle, these savings add up.

3. Improved Operator Experience & Noise/Vibration Reduction

EVs often offer smoother drivetrains, lower noise and less vibration—benefits in mining that can improve operator comfort and fatigue. In remote sites and shift-rosters, anything that improves well-being counts.

4. Future-Proofing & Site Ready-State

By deploying mine spec electric vehicles now, operators pre-empt future regulatory or site standard shifts. Being early-adopters can also assist in gaining site-access credibility. As Trend Rentals notes, the “future of mine spec vehicles” includes EVs, autonomy and smart-fleet tech.

5. Potential for Renewable Power Integration

If a mine site has solar/wind or off-grid power, electric vehicles can integrate into renewable energy systems, reduce diesel genset reliance, and potentially use vehicle-to-grid (V2G) or idle battery storage in future. South Australia’s EVSE standards provide a hint of the infrastructure angle.

The Disadvantages & Barriers

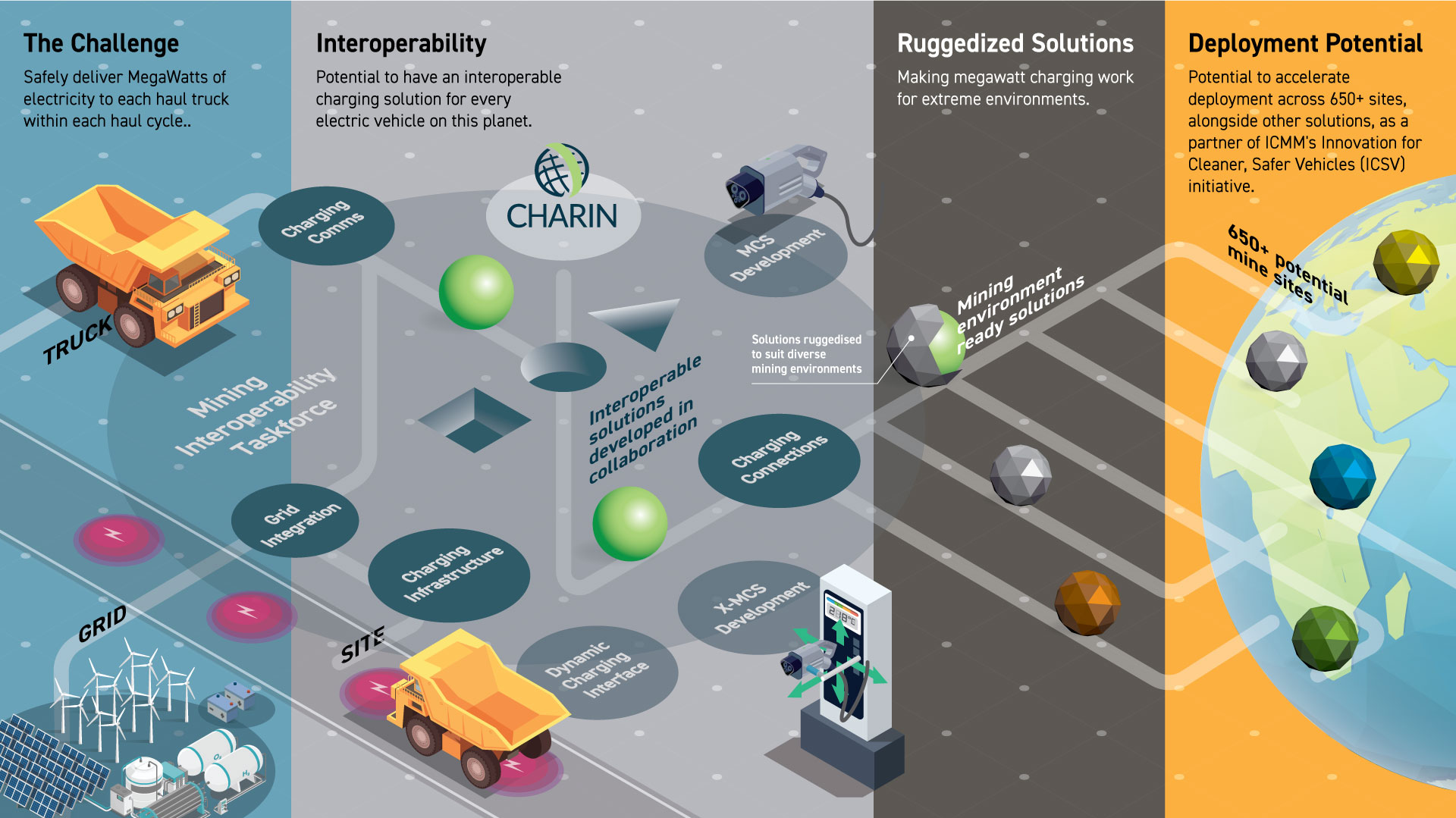

1. Charging Infrastructure & Range Constraints

Remote mining sites often lack extensive EV charging infrastructure. Long travel distances, rugged terrain and heavy loads exacerbate this. Without robust charging (including DC fast-charge or dedicated site chargers), EV solutions may struggle.

2. Up-front Cost & Fit-Out Complexity

EV platforms may carry higher initial cost than diesel equivalents. In addition, when a vehicle must be “mine-spec”, additional fit-outs (ROPS/FOPS, fire suppression, isolation switches, heavy-duty tyres, UHF comms etc) still apply — this adds to complexity and cost.

3. Battery Durability & Environmental Conditions

Mining operations can expose vehicles to extreme temperatures, heavy dust, shock/impact loads, remote servicing. Batteries are sensitive to environment and require proper HVAC/thermal management and ruggedisation to survive long-term. Some EVs may require adaptation for mining-level durability.

4. Payload/Heavy-Duty Capability & GVM Considerations

Some current EVs may sacrifice payload or towing compared to traditional diesel vehicles or may need additional engineering for heavy-duty mining duty. The barring: ensuring the EV meets the same GVM/haul capability as required by site.

5. Compliance & Certification Challenges

While EVs offer many benefits, they must still comply with mine-spec modifications, certifications, and site operator standards (ROPS/FOPS, isolation switch, fire suppression etc). New tech often means new certification pathways, which can delay deployment.

Compliance & Regulatory Landscape in Australia

Key Compliance Areas for Mine Spec Vehicles

Broadly speaking, compliance for mine spec vehicles in Australia covers:

- Safety structures (ROPS, FOPS)

- Fire-suppression systems, extinguishers

- Battery isolation switches / electrical safe-shutdown systems

- Lighting, UHF/VHF radios, communication systems

- Brakes, heavy-duty tyres, suspension / GVM accommodations

- Operator/driver controls, monitoring, IVMS systems

For EVs/hybrids specifically, additional considerations include: charger installation standards (EVSE), integration with site power, battery management and ruggedisation. For example, EVSE standards in South Australia cover infrastructure for vehicle-to-grid installations.

Site Operator Requirements & Corporate Standards

Major mining corporations (e.g., BHP) have published mine-spec vehicle requirements which include safety ratings, modifications, prohibitions on certain aftermarket changes etc. These provide a benchmark for any vehicle, including EV or hybrid, entering their sites.

Incentives & Emissions Framework

Australia’s push for fleet electrification and emissions reduction is gaining pace. Organisations such as AUSEV offer data and reports to support fleet electrification decisions. This means that fleet managers of mine-spec vehicles must consider their emissions profile, not just the technical fit-out.

Practical Certification for EVs on-Site

The transition to EVs will require new certification steps to integrate battery systems and fit-outs with the mine-spec framework — including reviewing battery isolation, underbody protection (for battery pack), thermal management systems, charger safety, and site-specific risk assessment of EV hazards (e.g., high-voltage circuits in remote operations). EV or hybrid vehicles proposed for hire by rental providers must be site-ready and compliant.

Practical Considerations for Transitioning to Mine Spec Electric Vehicles

1. Site Assessment & Fit-Out Gap Analysis

Start with assessing the site’s current fleet operations and infrastructure. Key questions:

- What distances and loads do vehicles cover?

- What terrain and environmental conditions?

- What charging infrastructure exists (or can be built)?

- What site-spec modifications are required (ROPS/FOPS, fire suppression, etc)?

This gap analysis will define whether EV/hybrid is viable for a given vehicle category.

2. Selecting the Right Vehicle Category

Not all vehicles are equal. For light-vehicle (LV) site-spec use (mine-spec utes, 4×4s) EV/hybrid may be practical sooner. For heavy-haul trucks, battery technology may not yet fit. Some providers already offer EV 4×4s for mine spec.

3. Charging Infrastructure & Energy Management

Implementing EVs requires charging strategy: AC/DC chargers, site power capacity, off-peak vs on-peak use, battery management, backup power, integration with renewable energy if available. Rental providers may offer turnkey solutions. For example, Kuuwa’s fleet hire in WA integrates on-site charging with EV/hybrids.

4. Maintenance & Operator Training

EVs operate differently to diesel/hybrid. Training operators on new systems (EV controls, thermal management, recovery, hazards) is vital. Maintenance teams need to understand battery systems, high-voltage circuits, diagnostics and fit-out integration. Fit-out providers must consider the EV architecture when adding mine-spec modifications.

5. Cost-Benefit & Total Cost of Ownership (TCO)

While EV up-front cost and infrastructure investment are higher, over time the savings from fuel, maintenance and operational efficiency can tip the balance. When evaluating, include: vehicle cost, charger cost, installation, grid upgrades, downtime, salvage value, emissions incentives, regulatory risk, and fuel cost volatility.

6. Hire/Rental Model Integration

If you contract or hire site-spec vehicles (as many operations do), work with a provider who offers mine-spec EV/hybrid options. Trend Rentals already delivers site-spec vehicle hire and coverage of remote-site operations. Link their fleet and capability into your plan. (See the Trend Rentals site-spec hire page.)

[Interlink note: For site-spec vehicle hire options, see Trend Rentals’ fleet page: Site Spec Vehicle Hire – Trend Rentals.]

7. Phased Roll-Out Strategy

For many operations, full electrification may not yet be feasible. A phased strategy works:

- Pilot EV/hybrid vehicles in less-demanding roles or site offices.

- Monitor performance, charging behaviour, maintenance patterns.

- Scale gradually and use learnings to upgrade heavier-duty categories.

How Hire Providers Can Support the Transition

Companies like Trend Rentals, which already supply civil, mine & site-spec vehicle hire, can play a critical role in enabling EV/hybrid transition:

- Offer a fleet of mine-spec EV/hybrid ready vehicles (with compliance fit-out included)

- Manage maintenance, charging infrastructure, lifecycle and upgrades

- Provide flexible hire terms so operations can trial EV/hybrid before full transition

- Ensure vehicles arrive site-ready with required mine-spec certification and documentation

This partnership model smooths implementation for operations and shifts some of the infrastructure burden onto the specialist provider.

Case-Study Snapshot

While specific publicly-detailed case studies are still emerging, the shift is real. For example, mining-fleet hire specialists in WA are already offering full electric (battery-electric) and hybrid vehicles for mine-spec hire, with turnkey charging solutions. And manufacturers such as MEVCO are marketing “mine-spec EVs for Australia” designed for mining conditions.

This suggests the market is shifting from concept to deployment, particularly for light-vehicles and regional operations.

Key Metrics to Monitor in Deployment

To ensure success with mine spec electric vehicles, track these metrics:

- Kilometres per shift & per vehicle (to validate range adequacy)

- Charging downtime and availability (charger uptime, queueing)

- Fuel cost savings / kWh cost vs diesel litre cost

- Maintenance cost per km / shift before vs after

- Downtime incidents related to fit-out, EV systems or battery

- Emissions reduction (CO₂e savings)

- Operator feedback (comfort, noise, handling)

- Compliance incidents or fit-out failures

Final Thoughts & Recommendations

The evolution toward mine spec electric vehicles is not just desirable—it’s inevitable. For mining operations, hire-partners and fleet managers alike, the question is less if and more when & how. By understanding the advantages, preparing for the challenges and building it into compliance and operational systems, you will be ahead of the curve.

Here are some recommended next steps:

- Initiate a pilot programme for mine-spec EV/hybrid in a defined fleet segment

- Collaborate with hire-providers or specialists such as Trend Rentals to obtain site-ready, compliant vehicles

- Invest early in charging infrastructure and energy integration (especially if renewable generation exists on-site)

- Develop maintenance/training protocols specific to EV/TUC battery systems and mine-spec fit-outs

- Embed monitoring and data analytics to track performance and build business case for scaling

- Communicate sustainability benefits internally and externally (ESG, stakeholder reporting)

When you combine rigorous compliance (ROPS/FOPS, fit-out, site-operator standards) with the strategic benefits of EV/hybrid, you create a fleet that’s resilient, future-proof and aligned with both operational demands and sustainability imperatives.