In high-risk environments where rotating shift crews use shared vehicles—think mining, construction, transport projects—the handover of vehicles between shifts is more than convenience. It’s about safety, compliance and operational continuity. A formalised vehicle handover checklist is the backbone of this process. When done well it reduces incidents, prevents misunderstandings and keeps vehicles performing.

Below is a deep-dive into the process: why it matters, key stakeholders, how to design and execute your checklist, how it fits into shift change culture and how to embed it into fleets such as those hired from Trend Rentals (who specialise in site-spec, mine-spec vehicles) for remote / rotating-crew use. We’ll also include a detailed infographic to visualise the flow.

Why a Formal Handover Matters

Vehicles used by rotating crews often travel long hours, across remote sites and under heavy duty. Without a structured handover:

- Minor issues may be missed and become major faults during a next shift.

- Responsibility may be ambiguous—who noticed the damage, who logged the mileage, who topped up fluids?

- Safety-critical features (lights, beacon, UHF radio, fire extinguisher) might not be checked between shifts.

- When using hired vehicles (eg via Trend Rentals’ site/spec fleet) the owner-operator needs to ensure compliance and the hirer needs to ensure asset integrity.

For example, Trend Rentals promotes their civil, mine & site spec vehicle hire fleet with remote-site delivery and full fit-out (bull bar, UHF radio, beacon, fire extinguisher, reflective tape etc). That means the handover checklist must include the additional site-specific fit-out components.

Stakeholders & Roles in the Handover Process

- Outgoing Crew / Shift – performs end-of-shift checks, fills out the checklist, reports issues, logs vehicle condition.

- Incoming Crew – receives brief, inspects vehicle condition, acknowledges checklist, logs mileage/fuel/defects.

- Fleet Manager / Site Supervisor – ensures handover process is formalised, records are kept, follow-up on reported issues.

- Maintenance & Compliance Team – acts on defects, logs repairs, ensures vehicle remains site-spec compliant (especially for mine-spec).

- Vehicle Provider / Hire Partner – e.g., Trend Rentals: ensures vehicle delivered with correct spec, documentation, safety gear.

Designing Your Vehicle Handover Checklist

A good checklist covers five major categories:

a) Administrative / Document Items

- Vehicle ID, registration, odometer reading.

- Shift date/time, outgoing crew name, incoming crew name.

- Rental agreement or internal fleet record (for hired vehicles).

- Certification of site-spec fit-out (if applicable).

- Insurance / compliance document confirmation.

b) Vehicle Exterior Condition

- Body damage, glass damage, tyres, wheels, mirrors.

- Bull bar, tow bar, accessories fit-out (if site spec).

- Lights (head, tail, beacon), reflectives, signage.

- Fuel level, oil/water check.

c) Vehicle Interior / Equipment

- Cleanliness, seats, belts.

- Dash warning lights, infotainment, UHF radio (if fitted).

- Fire extinguisher presence and expiry.

- First-aid kit, safety gear, cargo nets, wheel chocks (again if site spec).

- Tools, paperwork (logbook, fuel card).

d) Mechanical / Operational Checks

- Engine start, idle smooth.

- Brakes, steering, suspension.

- Fluids: coolant, oil, brake fluid.

- Tyre pressure and tread.

- Functioning of 4WD or special modes if site spec.

- Any fault codes or recent repairs.

e) Handover Notes & Next Steps

- Defects found and logged.

- Date/time for next service.

- Repairs required or scheduled.

- Special instructions for incoming shift (eg different route, heavy load).

- Signature or electronic acknowledgement of outgoing and incoming crew.

Step-by-Step: Executing the Handover

- Pre-handover briefing (5-10min): Outgoing crew summarises performance, route, any issues.

- Inspection using checklist: Outgoing completes checklist, photographs damage.

- Incoming inspection: Incoming crew reviews condition, completes their part, raises any new concerns.

- Sign-off and documentation: Both crews (or digital system) confirm handover. Record retained in fleet system.

- Follow-up action: Fleet manager reviews defects, schedules repairs, updates next shift.

- Continuous improvement: Review trend of issues (battery failure, tyres) to adjust maintenance regime.

Tips and Best Practices for Rotating Shift Crews

- Standardised process: Make the checklist the only version in use. No ad-hoc variations.

- Digital capture: Use tablets or mobile forms so photos and timestamps are logged.

- Include remote/after-hours shifts: Ensure the process works 24/7—crews arriving at odd hours still follow procedures.

- Use photos: Visual evidence helps resolve disputes over damage and ensures clarity.

- Training & onboarding: Incoming crews must be trained on use of the checklist and fit-out features (especially site-spec vehicles).

- Ensure handover time buffer: Don’t rush; allow 10-15 minutes for the handover even during shift change.

- Make it visible: Display the checklist and handover protocols in the depot or on the vehicle via QR code.

- Review metrics: Track number of defects reported, repeat issues, downtime following handover. Use this data for improvement.

When Hiring Vehicles: Integrating with Provider Processes

If your fleet includes hired vehicles from a provider like Trend Rentals, consider these extra steps:

- Make sure your handover checklist references and aligns with the supplier’s maintenance and inspection schedule (Trend Rentals’ site-spec vehicles come with fit-out and maintenance features).

- At pickup, perform a joint inspection with the rental provider and document pre-hire condition.

- Include column on the checklist for “Hirer vs Provider specification check” to verify accessories, regulatory compliance.

- Ensure return handover is equally formalised between final crew and provider to avoid damage disputes.

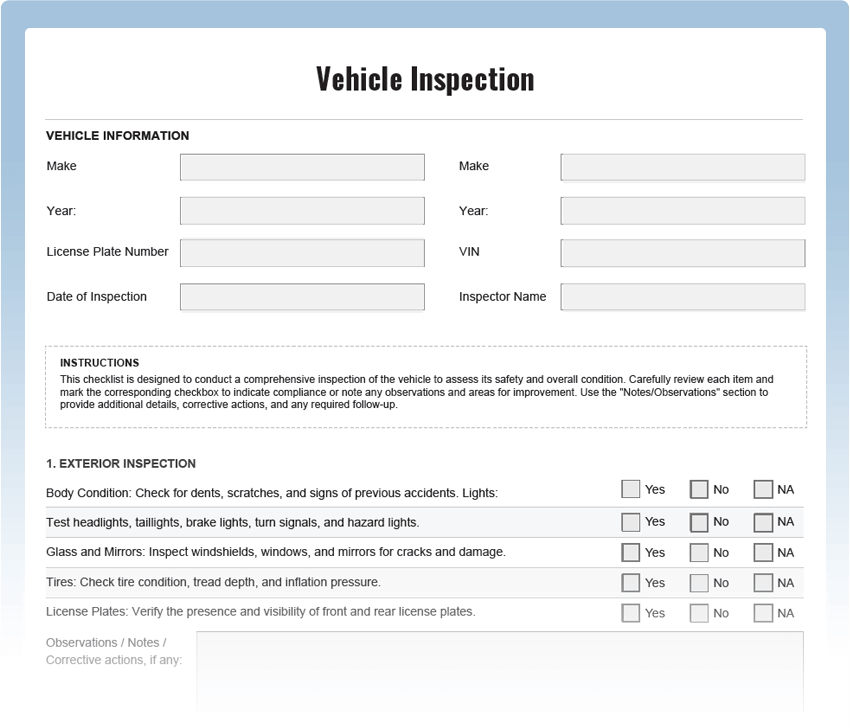

Sample Vehicle Handover Checklist (Template Outline)

Vehicle ID: _______ Date: _______ Outgoing Shift: _______ Incoming Shift: _______

1. Admin / Docs

- Registration number _______

- Odometer reading _______

- Fit-out checklist completed (Y/N)

- Insurance & rental documentation present (Y/N)

2. Exterior Condition - Body damage [ ] ok [ ] issues (describe)

- Tyres/wheels tread & pressure [ ] ok [ ] issues

- Lights & beacon [ ] ok [ ] issues

3. Interior & Equipment - Seats, belts [ ] ok [ ] issues

- UHF radio & accessories [ ] ok [ ] issues

- Fire extinguisher, first aid kit [ ] ok [ ] issues

4. Mechanical / Operational - Engine start & idle [ ] ok [ ] issues

- Brakes & steering [ ] ok [ ] issues

- Fluids top-up [ ] ok [ ] issues

5. Handover Notes & Repairs - Defects logged: _______

- Repairs scheduled: _______

- Incoming crew special instructions: _______

Sign-off

Outgoing Crew: _______ Incoming Crew: _______

Embedding the Culture of Safe Handover

To make this process sustainable and effective, you must embed it into your team’s culture:

- Celebrate adherence to the handover checklist—reward crews that consistently complete well.

- Use real-life incident reviews to show how gaps in handover caused issues (tyre blowouts, missing UHF radios, unseen damage).

- Make the handover checklist a core part of induction for new staff and refresher for seasoned crews.

- Audits: Periodically review handover documentation for completeness and quality.

- Link your vehicle handover process with your broader shift-change process. Handover of vehicle should not be seen in isolation but part of the shift-change briefing.

Common Pitfalls & How to Avoid Them

- Rushing the handover: Crews wanting to get on the road quickly skip steps. Solution: build buffer time.

- Poor documentation: Handwritten checklists illegible or lost. Solution: digital forms with mandatory fields.

- Incoming crew blind to outgoing notes: Outgoing doesn’t brief incoming properly. Solution: formalised handover briefing.

- Absence of follow-up: Defects reported but not addressed. Solution: fleet manager tracks repairs and closure.

- Mismatch between vehicle fit-out and checklist: Especially when a hired vehicle has site-spec features. Solution: update checklist when vehicle spec changes and liaise with provider (e.g., Trend Rentals).

Tools & Technology to Support the Process

- Mobile inspection apps: Use smartphones/tablets with photo capture and timestamp.

- Fleet management software: Logs handover data, defect history, driver shifts.

- QR code on vehicle: Directs to the checklist form specific to that vehicle.

- Dashboard metrics: Track handover completion rates and defect trends.

- Integration with rental provider portal: Where using hired vehicles, ensure handover data is shared with the provider for transparency.

Why a Strong Handover Process is Especially Important for Remote & Mine-Spec Fleets

In remote site operations—and for vehicles supplied by companies like Trend Rentals specialising in mine-spec and site-spec vehicles—risks are higher: long drives, poor terrain, extended shifts, isolated breakdowns. Trend Rentals emphasises custom fit-outs (bull bar, UHF radio, antlers, beacon etc) and remote-site delivery. This means handover checklists must cover the extra gear and ensure the vehicle is truly ready for the scope of the upcoming shift. Without this, a missing beacon light or faulty UHF radio could slow operations, lead to non-compliance or safety incident.

Infographic: A Colourful Visual Overview

Conclusion

A well-run vehicle handover process backed by a rigorous vehicle handover checklist is not optional—it’s essential for safe, efficient operations in environments where shared vehicles serve rotating shift crews. Whether you’re managing an internal fleet or hiring specialised vehicles from companies like Trend Rentals, the structure, accountability and consistency provided by the handover process pays dividends in safety, operational continuity and asset longevity.

Take the time to design your checklist, train your crews, integrate documentation, and review your process regularly. The result: fewer surprises, fewer breakdowns, and a fleet that keeps moving—safely.