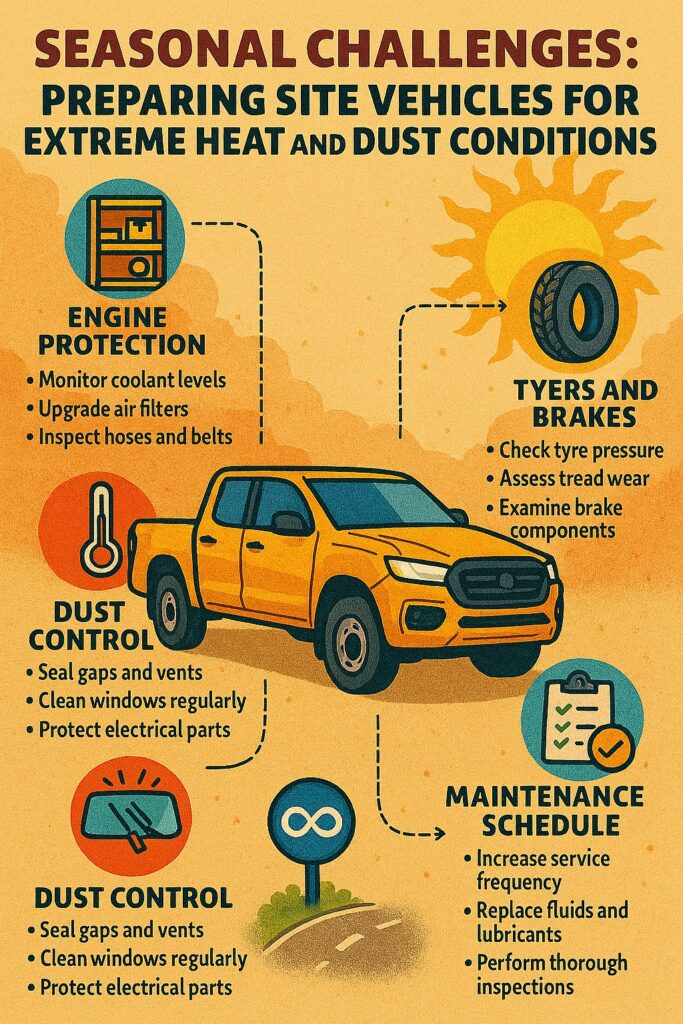

Extreme heat and heavy dust are more than just uncomfortable conditions—they’re formidable challenges that can cripple site vehicles, cause breakdowns, and increase maintenance costs if operators aren’t prepared. Whether you’re running a construction fleet, mobile workshop, event support vehicle, or delivery unit, proactive seasonal preparation can extend vehicle life, ensure safety, and minimise downtime.

This comprehensive guide breaks down everything you need to know to prepare site vehicles for extreme heat and dust conditions, with clear strategies, maintenance checklists, and links to essential resources on TrendRentals.com.au to help you equip, safeguard, and optimise your fleet for the harshest conditions.

Why Extreme Heat and Dust Matter for Site Vehicles

For operators working in regions with scorching summers and frequent dust storms — such as central Australia, mining zones, outback construction sites, or desert event locations — environmental stressors directly impact your vehicles’ performance.

High temperatures and airborne dust can lead to:

- Overheating engines

- Clogged filters and air intake systems

- Accelerated wear on belts, hoses & seals

- Electrical system failures

- Poor cabin comfort and operator fatigue

Understanding the specific risks prepares you to mitigate them effectively.

1. Pre-Season Planning: Start Early, Act Smart

Preparing your vehicles well before the hottest, dustiest months is the foundation of seasonal resilience.

a. Create a Seasonal Maintenance Calendar

List all key tasks with due dates (e.g., cooler fluid checks before November, dust seal inspections before August).

b. Review Historical Climate Data

If your sites regularly surpass 35–40°C, plan for more frequent service intervals.

c. Train Your Team

Operators and on-site technicians should understand:

- Symptoms of heat stress in vehicles

- Early signs of dust penetration

- Emergency field maintenance steps

👉 Learn more about fleet training resources: Vehicle Operator Safety & Training

2. Cooling System Health: The Heart of Heat Preparedness

When ambient temperatures soar above 40°C, a vehicle’s cooling system is under intense pressure.

a. Coolant System Flush & Replace

Old or degraded coolant loses effectiveness.

- Flush the system annually

- Use coolant with correct heat tolerance

- Check for leaks

b. Radiator & Fan Inspection

Dust buildup blocks airflow through the radiator, decreasing cooling capacity.

- Clean radiator fins

- Inspect fan belts for wear

- Ensure electric fans operate reliably

c. Thermostat and Water Pump Check

A failed thermostat or water pump under extreme heat can lead to catastrophic engine damage.

d. Consider Upgraded Cooling Solutions

Heavy-duty radiators and high-capacity fans can be worth the cost for vehicles in severe environments.

3. Air Filtration: Dust Defence for Engines and Cabins

Dust is insidious — it infiltrates air intakes, abrades engine internals, and degrades cabin air quality.

a. Engine Air Filters

Replace filters more frequently during dusty seasons.

- Inspect weekly in high-dust zones

- Upgrade to heavy-duty filters where available

b. Cabin Air Filters

Protect operator health and comfort.

- Replace every service interval

- Consider high-efficiency particulate filters

4. Cooling Upgrades for Operator Comfort and Efficiency

Extreme heat doesn’t just harm engines — it affects the people operating the vehicles.

a. Air Conditioning Service

Ensure the A/C system is charged and functioning before heat spikes.

- Check refrigerant levels

- Inspect compressor, belts & condenser

b. Sunshades & Window Tints

These passive upgrades reduce cabin heat gain.

c. Auxiliary Fans

Install dashboard or roof-mounted fans for supplemental airflow.

d. Hydration Stations

Include insulated water storage and coolers for operators on long shifts.

5. Fluids, Lubricants & Thermal Stability

High heat accelerates fluid breakdown and changes viscosity — which impacts engine, transmission, and hydraulic performance.

a. Engine Oil

Switch to higher temperature-rated oils during the hottest months.

b. Transmission & Differential Fluids

Heat causes breakdown, leading to gear wear or failure.

- Use heavy-duty or synthetic variants

- Inspect levels weekly

c. Brake Fluid & Hydraulic Fluids

Ensure all fluids are clean and at proper levels.

6. Electrical Systems: Heat and Dust-Proofing Your Wiring

Electronics failures are common in dust-laden, high-temperature conditions.

a. Battery Maintenance

Heat shortens battery life.

- Check charge and hold capacity

- Clean terminals

- Consider heat shields

b. Wiring & Connectors

Dust and heat can corrode contacts.

- Use sealed connectors where possible

- Inspect harnesses for melting or brittleness

7. Brakes, Tires, and Suspension: Safety Under Strain

The drivetrain and chassis components face extra stress in dusty, hot environments.

a. Tire Checks

Heat increases tire pressure and wear.

- Inspect tread depth

- Monitor air pressure daily

- Equip heavy-duty or heat-rated tires if needed

b. Brake Components

Dust infiltrates brake pads and rotors.

- Clean components regularly

- Inspect for premature wear

c. Suspension

Dust can degrade bushings and seals.

- Grease joints routinely

- Replace worn parts before failures occur

8. Protective Coatings & Bodywork Strategies

Exterior protection keeps dust and heat from accelerating corrosion and paint fade.

a. UV-Resistant Paint & Wraps

Protect body panels from sun damage and make cleaned dust removal easier.

b. Underbody Protection

Stone guards and sealants prevent dust abrasion on critical undercarriage parts.

9. Dust Control Accessories & Best Practices

Dust isn’t just airborne — it settles on every surface.

a. Door Seals & Weatherstrips

Ensure tight closure to prevent dust entry.

b. Air Intake Snorkels

Elevating air intakes reduces dust ingestion on very dusty sites.

c. Cab Mat & Interior Protection

Heavy-duty mats and washable seat covers make clean-up faster.

10. Operational Strategies to Minimise Heat & Dust Impact

Preparation extends beyond equipment — it’s also about how you operate.

a. Schedule Smart Work Hours

Avoid peak heat hours where practical. Early morning or evening tasks reduce heat stress on vehicles and people.

b. Rotation of Fleet

Rest vehicles between heavy duties to prevent overheating.

c. Idle Reduction

Excessive idling increases engine temperature and fuel use:

- Shut down engines when safe

- Use auxiliary power units if needed

d. Dust Suppression at Site

Work with site teams to implement dust control:

- Water trucks

- Windbreaks

- Vegetation barriers

11. Real-World Vehicle Preparation Checklists

To help you operationalise all of the above, here’s a ready-to-use seasonal vehicle preparation checklist:

Cooling & Fluids

✔ Coolant level & quality

✔ Radiator cleaned & inspected

✔ Thermostat & water pump tested

✔ Oil & filter upgraded for heat

Filtration

✔ Engine air filter replaced

✔ Cabin filter checked

✔ Heavy-duty filters fitted

Electrical

✔ Battery load tested

✔ Terminals cleaned

✔ Sealed connectors used

Operator Comfort

✔ A/C performance tested

✔ Sunshades installed

✔ Hydration plan in place

Tires & Brakes

✔ Tires pressure checked daily

✔ Brake pad & rotor inspection

✔ Heat-rated tires fitted as necessary

Protection

✔ Paint/UV wrap applied

✔ Underbody protection installed

✔ Door seals replaced

Documentation

✔ Maintenance logs updated

✔ Service intervals scheduled

✔ Operator training completed

Use this checklist quarterly to stay ahead of seasonal challenges.

12. Case Studies: How Prepared Operators Reduce Downtime

Case Study A — Construction Fleet in Outback NSW

By scheduling pre-season deep servicing and installing upgraded air filtration systems, this operator:

- Reduced overheating incidents by 78%

- Cut engine filter replacement costs by 40%

- Improved operator comfort scores

Their secret? Early planning and discipline in maintenance.

Case Study B — Event Support Vehicles in the Red Centre

Event vehicles experienced heavy dust and extreme heat. By adding:

- Snorkels for air intakes

- Sealed electrical connectors

- Auxiliary shade structures

They kept all vehicles running reliably through two high-demand event seasons.

13. Budgeting for Seasonal Protection Upgrades

Effective preparation isn’t free — but the cost of inaction is higher.

Typical Upgrade Costs

| Upgrade | Typical Cost Range |

|---|---|

| Heavy-duty air filters | $50–$200 each |

| Cooling system upgrades | $300–$1,500 |

| Electrical protection kits | $200–$800 |

| UV paint wraps | $1,000–$4,000 |

| Snorkel installs | $150–$600 |

Budget in your annual plan for these upgrades — especially if you operate in heat/dust-prone regions.

14. Seasonal Document Templates & Tracking Tools

Organise your seasonal readiness with:

- Service schedule templates

- Heat & dust performance logs

- Operator inspection checklists

- Incident reporting forms

Use digital tools to save time and ensure accountability.

15. Future-Proofing Your Fleet Against Climate Extremes

Conditions are getting more extreme globally. Future-proof your vehicles with:

a. Telematics

Monitor engine temps, airflow, and fault codes in real time.

b. Predictive Maintenance

Use telematics data to schedule service before failures occur.

c. Heat-Resistant Component Upgrades

From high-temp seals to specialised coolant blends.

16. Common Mistakes Operators Make (and How to Avoid Them)

❌ Waiting Until Heat Hits

Reactive maintenance costs more and risks breakdowns.

Fix: Plan maintenance in cooler months.

❌ Underestimating Dust Impact

Dust penetrates where you least expect it.

Fix: Inspect seals and filters frequently.

❌ Skipping Operator Training

Even the best-prepared vehicles fail under poor operation.

Fix: Regular refresher training on heat/dust protocols.

17. Final Thoughts & Seasonal Readiness Mindset

Preparing your site vehicles for extreme heat and dust isn’t a one-off task — it’s a seasonal discipline that protects your investment, enhances safety, and keeps operations running smoothly under harsh conditions.

Start early, inspect thoroughly, equip wisely, and train consistently. With the strategies and checklists in this guide — plus support from TrendRentals.com.au resources — you can confidently tackle the toughest seasonal environments.

If you’d like a downloadable checklist or a custom seasonal preparation plan tailored to your fleet size and operating environment, just let me know — I can generate one for you!