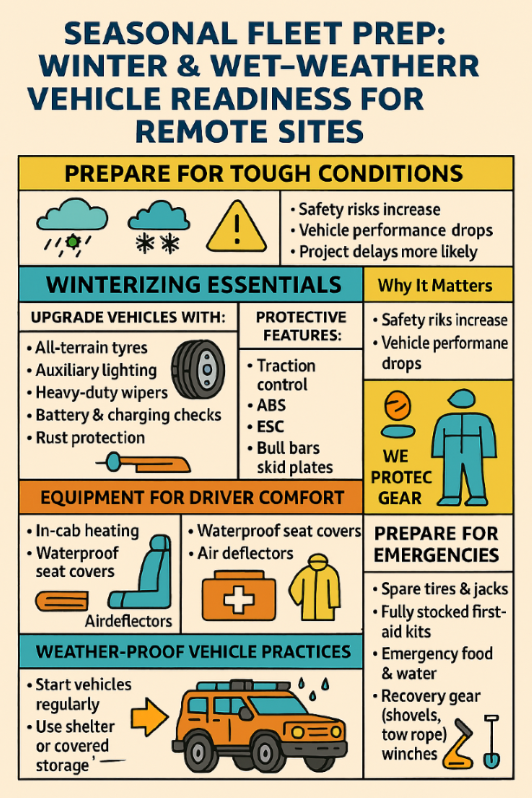

Preparing vehicles for winter and wet weather conditions at remote sites isn’t just good practice — it’s essential for safety, operational continuity, and cost control. From muddy roads to chilling temperatures and unpredictable storms, seasonal weather challenges can disrupt timelines, damage vehicles, and put crews at risk if fleet readiness isn’t prioritised.

In this comprehensive guide, we’ll explain:

- Seasonal weather risks at remote worksites

- Key maintenance tasks for wet and cold climates

- Safety and compliance considerations

- Essential gear and accessories for weather-proofing

- Planning strategies to minimise downtime

- Operational best practices and real-world scenarios

Whether you manage a mining fleet, construction vehicles, site support transport, or FIFO operations, this blog will ensure your vehicles are ready for winter and wet weather demands.

1. Understanding Winter & Wet Weather Risks in Remote Operations

Remote sites — especially in regions prone to heavy rain, flooding, freezing temperatures, or seasonal storms — present unique risks for vehicles:

- Traction loss, mud, and washed-out access roads

- Cold starts and battery failures

- Water ingress into electrical systems

- Corrosion and rust acceleration

- Reduced visibility and lighting issues

- Increased wear on tyres, brakes, and suspension

These risks impact not only vehicle reliability but also crew safety and compliance with site regulations. Proactive preparation minimises reactive repairs and costly delays.

2. Pre-Season Planning: Start Early and Be Strategic

A seasonal fleet preparation plan should begin well before winter or wet weather arrives. Early planning ensures vehicles aren’t rushed through checks and that critical parts are available.

a. Seasonal Maintenance Calendar

Create a detailed timeline that includes:

- Brake and suspension inspections

- Tyre checks and replacements

- Fluid changes with weather-appropriate grades

- Cooling and heating system servicing

- Electrical system reviews

b. Historical Weather Data Review

Analysing past weather patterns lets you anticipate peak wet and cold conditions, so you can schedule servicing and pre-deployment accordingly.

c. Operator Training

Ensure drivers and field teams understand:

- How to navigate slippery terrain

- When to stop operations due to weather

- How to perform basic checks before and after shifts

3. Essential Vehicle Checks Before Winter & Wet Seasons

Winter and wet weather affect key vehicle systems. Below are the most critical checks to perform:

a. Engine & Cooling System

Though cold climates reduce overheating risks, other issues such as coolant freezing or viscosity changes can occur.

👉 Ensure your cooling system is serviced with the correct antifreeze mix — this maintains temperature regulation and prevents blockages.

b. Battery & Electrical Systems

Cold temperatures dramatically reduce battery performance:

- Test battery capacity before winter

- Clean terminals and tighten connections

- Inspect starter motors and alternators

Water and moisture can also affect electrical systems. Check wiring, connectors, and seals to prevent water ingress.

c. Fluids & Lubricants

Winter weather warrants switching to cold-weather-friendly lubricants:

- Engine oil with correct cold temperature viscosity

- Brake fluid and transmission fluid checks

- Windshield washer fluid rated for low temperatures

d. Brakes & Suspension

Wet conditions and mud require responsive braking and robust suspension:

- Inspect brake pads, rotors and lines

- Look for suspension wear or damage

- Replace worn components before they fail

e. Heating & Defrost Systems

In minimum temperatures and wet conditions, clear visibility and cabin warmth aren’t luxuries — they’re safety essentials:

- Check heater core operation

- Test defrost systems on windscreens and mirrors

4. Tyres, Traction & Off-Road Performance

Tyres are the most direct interface between your vehicle and challenging weather conditions.

a. Tyre Tread & Pressure

Check tyre tread depth and replace tyres with significant wear. Proper inflation improves:

- Traction on mud, gravel and slick surfaces

- Tyre longevity

- Ride stability

Monitor pressure more frequently in cold weather — temperatures can cause pressure drops.

b. All-Terrain & Mud-Rated Tyres

For remote sites with unsealed roads, consider:

- All-terrain tyres

- Mud-terrain upgrades for off-road stability

- Carrying spares for long field deployments

This reduces the risk of blowouts and keeps vehicles mobile in unstable ground.

5. Protecting Against Water Damage

Wet weather isn’t just rain — it’s flooding, puddles, saturated surfaces, and standing water.

a. Seals & Weatherproofing

Inspect:

- Door and window seals

- Hatch gaskets

- Under-body shields

Replace any damaged seals to keep water out of cabins and critical compartments.

b. Snorkels & Raised Air Intakes

For site vehicles regularly traversing floodwater or deep puddles, consider:

- Snorkels

- Raised breather hoses

These prevent water from entering the air intake or engine, avoiding hydro-locking incidents.

c. Underbody Protection

Install:

- Skid plates

- Guard bars

- Corrosion-resistant coatings

These protect suspension, braking components, fuel tanks and electrical lines under harsh conditions.

6. Winter & Wet Weather Gear for Fleet Vehicles

The right accessories and seasonal gear make a major difference in readiness and reliability.

a. Emergency & Recovery Kits

Each vehicle should carry:

- Recovery straps and shackles

- Portable winch systems

- High-lift jacks

- Traction boards or sand ladders

These tools help crews recover vehicles stuck in mud or snow without waiting for external assistance.

b. Lighting & Visibility Upgrades

Low light, fog and heavy rain demand:

- Additional LED light bars

- Fog lights

- High-visibility reflective decals

Improved lighting enhances safety during short daylight hours and adverse conditions.

c. Weather-Resistant Floor Mats & Seat Covers

Protect vehicle interiors from moisture, dirt and corrosion with heavy-duty mats and seat covers — especially useful in muddy environments.

7. Fleet Documentation & Compliance in Seasonal Weather

Weather-related fleet preparation isn’t just physical — it’s documentation and compliance too.

a. Service Logs

Maintain updated:

- Inspection checklists

- Pre-trip records

- Maintenance logs

Documentation supports compliance audits and improves accountability across your fleet.

b. Weather Intervention Protocols

Draft standard operating procedures (SOPs) for:

- Severe weather shut-downs

- Vehicle movement restrictions during flooding

- When to evacuate or reschedule

Clear SOPs protect teams and reduce liability.

8. Operational Strategies for Remote, Seasonal Conditions

a. Staggered Usage

Rotate vehicles to avoid overuse of specific units during intense weather, distributing wear and tear evenly.

b. Weather Monitoring

Implement routine weather checks before dispatching crews. This arms operators with data to delay travel or work when extreme weather is forecast.

👉 While this guide focuses on preparedness, you can also incorporate seasonal planning templates and tools into your internal systems.

c. Centralised Vehicle Support Hubs

Where possible, establish support hubs:

- At camps or depots

- With basic servicing tools

- With contingency plans for parts delivery during storms

These hubs minimise downtime and give frontline crews reliable support.

9. Case Studies: Success in Seasonal Readiness

Case Study: Remote Mine Fleet in Tropical Wet Season

A mining operation in northern Australia faced heavy rains and frequent flooding during the wet season. By implementing a pre-season fleet prep plan that included:

- Waterproof seals and snorkels

- All-terrain tyres

- Recovery kits in every vehicle

- Strict service logs and SOPs

They reduced vehicle downtime by 47% and improved site safety records.

Case Study: Cold & Snow Challenges for Regional Construction

A regional construction fleet operating in cold winter climates saw battery failures and condensed moisture shortly after upgrades:

- Switch to low-temp oil grades

- Complete battery test and replacement before season

- Heated shelters for parked vehicles

The result was reliable weekly starts and fewer weather-related breakdowns.

10. Budgeting for Seasonal Readiness

Proper winter and wet weather preparation keeps vehicles safer, but it does require budgeting. Consider these cost components:

- Tyre replacements and all-terrain upgrades

- Weather-proofing seals

- Hydraulic and fluid changes

- Snorkels and underbody protection

- Emergency gear and accessories

Investing early in readiness often yields savings later through reduced repairs, fewer call-outs and better uptime.

👉 If you need flexible vehicle solutions during peak wet seasons, see our short-term hire options — ideal for remote sites when your own fleet is under maintenance or insufficient. Short-term vehicle hire supports remote fleet flexibility without long-term capital outlay.

11. Training & Team Preparedness

Vehicles aren’t the only thing needing prep — drivers and field crews do too.

a. Seasonal Weather Workshops

Train drivers on:

- Identifying unsafe terrain

- Proper use of recovery gear

- Cold start protocols

- “Stop work” criteria when conditions exceed safety thresholds

b. Simulated Adverse Conditions

Conduct controlled exercises in wet and muddy conditions. Familiarity builds confidence and improves real-world responses.

12. Useful Checklists for Immediate Action

Wet Weather Readiness Checklist

✔ Tyre tread & pressure check

✔ Seals & underbody protection inspected

✔ Snorkel & air intake conditions verified

✔ Recovery gear onboard

✔ Lighting systems upgraded

✔ Weather SOP posted in vehicles

Winter Readiness Checklist

✔ Battery load tested

✔ Cold-rated fluids installed

✔ Heater & defrost systems tested

✔ Emergency blankets & kits stored

✔ Visibility upgrades implemented

13. Partnering with the Right Vehicle Provider

Seasonal fleet prep often means balancing in-house fleets with hired vehicles. Providers like Trend Rentals help you stay operational with flexible vehicle options tailored to remote site demands.

Whether you need:

- Off-road-ready 4WDs

- Long-term seasonal hires

- Short-term replacements during service

- Compliant vehicles for site entry

14. Future Weather Trends & Fleet Resilience

Climate variability means seasonal extremes are intensifying. Fleet managers should plan for:

- More frequent storm events

- Longer wet seasons

- Greater temperature fluctuations

Building resilience now means fewer disruptions later.

Conclusion

Winter and wet weather conditions present real challenges for remote site fleets. But with the right preparation — from servicing, tyres, gear, documentation, and training — you can minimise disruptions and protect both vehicles and crews.

Seasonal prep isn’t a one-off task. It’s a discipline that keeps operations safe, compliant, and productive no matter the weather.

Start your seasonal fleet readiness plan today and make reliability in winter and wet weather a standard — not a risk.